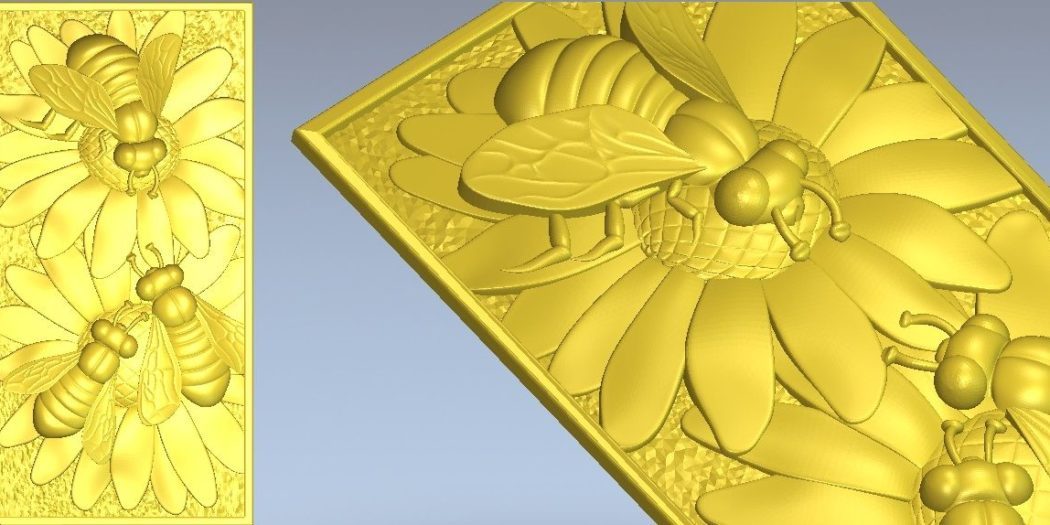

Staying within both processes limitations it is entirely possible to mill the same exact parts with each method. The other uses complex digital 3D surface structures and basically makes a file that replicates that 3D surface areasīoth methods can create 3 dimensional objects or entirely flat objects. One used 2D images to created somewhat 3D(appropriately named 2.5D) objects by using flat linear paths to define the tool paths that on a path to path basis can be cut to certain depths.

I think the confusion that is coming in is that it is not about how dimensional of an object that can be created that defines it but the process in which the nc file is created and the way the machine produces the part. Sort of complex.Up down left right and all around in unison. Not entirely farmiliar but 5 and 6 axis but I believe theymay have the ability to somewhat use a hybred of both methods.

3D is created with a rastering effect where the machine moves simultaniousley in multiply axis and actually traces/ mimicks the cutting tool along the surfaces dictated by the file.Basically to the left or right with a whole series of ups and downs along the way. ***3D is based on a three dimensional surface or solid part file and not just a flat drawing. Where as 2D requires manual positioning of the Z position.ĢD and 2.5 are generally a plotted path or collection of paths made up of of segments(curves and lines). This alllows for varied depth with regards to pockets and islands and such in one NC file. ***2.5 is based on a flat drawing such as a DXF but unlike 2d which only controls X and Y movement there is control for Z movement as well. Hi,I am using a 2.5D Gibbs Cam package for the last 8 years and have found it excellent.Basically you draw up in 2d in the gibbs or import in a dxf cad drawing in 2d into the gibbs and use this drawing to do your cnc program by just selecting cutter type etc and set your depth for machining and it will do it.Very basic but here is where it gets good,If you have a rectangular hole that you want to mill with a draft angle on the inside you can using a standard endmill to contour(take small cuts) and create the desired shape.The problem with this program is that if one wall of the rectangular hole needs to be a different angle it will NOT do it.Also if you want to cut a curved shape into the wall you can do this by also drawing somewhere seperate on the screen a "drive curve" so you select your rectangle and instead of giving it a zdepth and angle you select what is called a swept shape and it will cut the rectangular pocket with a drivecurved wall.I think Gibbs do a direct input version for solidworks models that is very reasonable.Remember to ask whoever is supplying your software do they have a postproccesor to suit your machine and its controller.Hope this helps.Regards.

0 kommentar(er)

0 kommentar(er)